The comprehensive range of tekMag magnetic flow sensors operate on the Principle of Faraday’s Law, which states when a conductor moves through a permanent or an electro-magnetic field B, a signal voltage U is generated, whose amplitude is proportional to the mean velocity v of the conductor. The conductor is the measured media flowing through the magnetic flow sensor. The generated voltage is measured across 2 electrodes situated diametrically opposite each other in the walls of an obstruction free flow tube, diameter d. The flow tube and electrodes are insulated from each other by a thick, non-microporous liner of various materials. The magnetic field is normally generated by coils, whose axes are at 90º to the electrodes All tekMags are bi-directional.

From Faraday’s Law: U = k. B. v. d

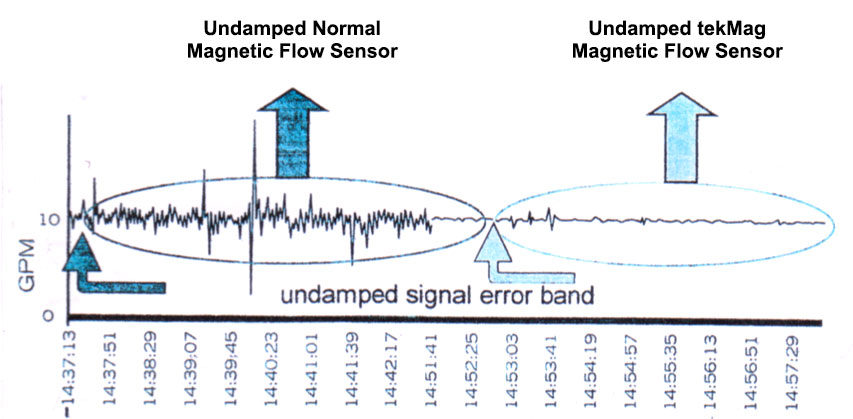

Initiating a step further, engineers and scientists at tekflo sensors pioneered an advanced solution to signal quality. They were the first to prove that the signal to media noise ratio was inherently proportional to the multiplication of the magnetizing current and the square root of the cube of the exciter frequency for a given electrically pulsed coil. This further resulted in a fast time constant, which in turn allowed true mathematical averaging of irregular pulsatile or noisy flow.

The quality of the signal, or more precisely, the signal to media noise ratio, is a dimensionless function of:

Signal Quality Factor = Im . t . P. f1.5 . L0.5

Where Im = magnetizing current t = signal evaluation period

P = the excitation polarization, where P =1 for uni-polar and P = 2 for bi-polar

f = the exciter frequency L = the coil inductance, normally measured in Henrys

The Practical tekMag Difference

1) A typical normal 150mm (6”) diameter pulsed DC magnetic flow sensor has a magnetizing current Im of 0.1 Amps peak to peak, an evaluation time of 20ms, a bi-polar excitation of P = 2, an exciter frequency of 4 Hz and a coil inductance of 0.5 Henry.

Normal Signal Quality Factor = 0.1 x 20 x 2 x 41.5 x 0.5 0.5 = 181

2) A typical tekMag 150mm (6”) high powered pulsed DC magnetic flow sensor has a magnetizing current Im of 0.3 Amps peak to peak, an evaluation time of 20ms, a bi-polar excitation of P = 2, an exciter frequency of 12 Hz and a coil inductance of 0.5 Henry.

tekMag Signal Quality Factor = 0.3 x 20 x 2 x 121.5 x 0.50.5 = 353

This demonstrates that tekMag, through unique design, has a Signal Quality Factor typically 2 times greater than normal pulsed DC magnetic flow sensors.

Media such as greasy raw sewage, paper pulp, slurries or media causing calcium carbide coatings create piezo (impact) or tribo (frictional) electrical noise at the electrodes of all magmeters. These cannot be simply damped out, as is often attempted, since the noise is irregular in frequency and magnitude. A true average is not accomplished, causing puzzling and costly errors.

This problem does not exist with tekMags. They have the highest possible magnetizing current at the highest practical frequency, combined with low power consumption, at probably the lowest prices on the market. This allows for the first time a truly economical method to guarantee the measurement of problem media on-site, without loss of accuracy and based on a USA NIST traceable customized calibration.

tekMag Features Summary

- tekMag technology offers the highest possible signal : media noise ratio

- Suitable for permanent coatings of sewage grease

- High accuracy to ± 0.25% of reading > 0.1 m/s (0.3 fps)

- Resolution to 1000th of range

- Calibration Certificates with traceability to USA NIST and other international standards

- Quality Assurance to ISO 9001

- Guaranteed operation to customized specification straight from the packing crate

- Range of sizes 2 – 2000mm (0.08” – 80”)

- Meets European EMC Conformity Standards to EN 61326 – 1 for industrial locations

- Meets European Pressure Equipment Directive – Sound Engineering Practice

For further details consult robert.batey@tekflosensors.com and www.tekflosensors.com