Tekflo manufactures the most comprehensive range of averaging Pitots to cover more applications from clean to very dirty gases, liquids, saturated or superheated steam, as well as air in large rectangular or circular ducts with limited straight runs.

They measure differential pressure to infer flow, in accordance with classical Bernoulli Theory. To be noted is Bernoulli Theory assumes a true static pressure.

Only tekProbe PR3 for high accuracy multivariable applications accomplishes this ! Included in various tekProbe options are:

Features

- PR3 – the only averaging Pitot to measure impact pressure and true static pressure to provide uncompromised accurate volumetric, mass or energy flow sensing

- PR3 – the only averaging Pitot with a linearity to ± 0.5% of reading > 0.5 m/s (1.6 fps) liquids, or gas and steam with Reynolds Numbers > 50,000

- PR3 averaging Pitot uniquely offers integral all-digital sensing with true static pressure computation

- PR3 – the only averaging Pitot with 6 sensing ports meeting USA 40CFR60 Code of Federal Regulations and ASHRAE Handbook and log Tchebycheff rule to ISO 3966 for a single diameter

- PR3 – the only multi-variable averaging Pitot with dp, true static pressure, tekProbe protected temperature sensor, all digital dp cell, steam flow condensate pots, valves, manifolds

- PR4, 5 – bi-directional averaging Pitot to 320 bar g (4640 psig), -40 to +250°C, under pressure option

- PR6 – the bi-directional Pitot specially designed for very dirty liquids, gases and steam

- PR7 and 8 tekProbes custom manufactured for large rectangular or circular air ducts with short runs

- USA NIST and CEGB Hams Hall (UK Accreditation Service) traceable, customized Flow Certificate

- FM and CSA Explosion Proof Approval to Class 1, Div 1, or FM, CSA and ATEX intrinsic safety

- FOUNDATION Fieldbus, RS 485 Modbus and 4-20mA outputs with HART Protocols

- tekProbe installation costs > 25% less than 100mm orifice plate, and > 75% less than 500mm orifice

- All Tekflo DP cells meet European Directive EN 61326 – 1/A1 Electro Magnetic Immunity

Specification

The tekProbe PR3 Multivariable Averaging Pitot Flow Sensor brings new advances in the art of accurate, wide ranging, insertion averaging Pitot tubes for use with liquids, gases and steam. Pipe or duct sizes are from 50mm to 2000mm (2” to 80”). The tekProbe PR3 introduces for the first time a multi-port insertion, multivariable averaging system, with noise free differential pressure (dp) between flow impact pressure and a true static pressure. The differential pressure is proportional to mass or volumetric flow rate.

Other averaging Pitots measure the differential between impact pressure and suction, or have an erroneously called ‘static’ pressure port on the sensor itself. Both methods compromise signal to noise ratio, the non- linearity of flow coefficient, as well as providing an erroneous static pressure signal to the dp cell. This results in compromised accurate flow measurement and multivariable computation uncertainty.

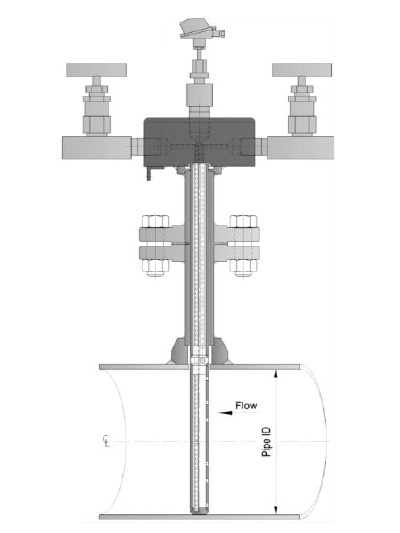

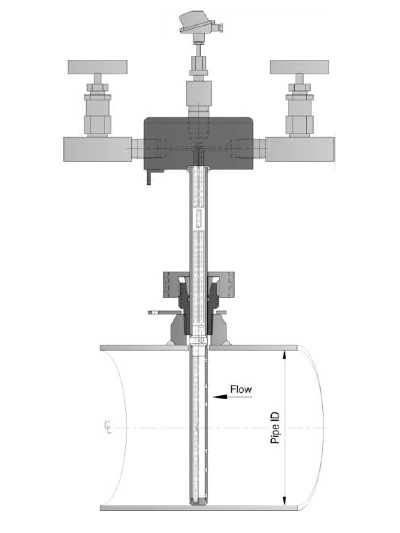

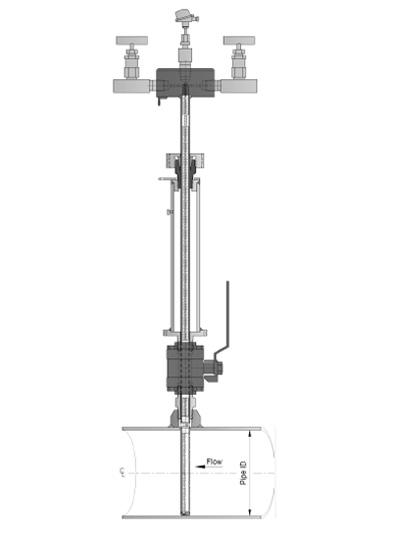

The tekProbe PR3 averages velocity profile in a pipe or duct normally with a single averaging sensor. Six impact pressure ports are spaced on the upstream side of the tekProbe, in accordance with USA Code of Federal Regulations 40CFR60, the ASRAE Handbook, and the internationally accepted log Tchebycheff rule to ISO 3966. The true static pressure is uniquely sensed and protected by the tekProbe’s pipe/duct connection, away from the flow cross section, such that it is unaffected by the turbulent media and provides a noise free signal.

The tekProbe PR3 in its simplest form may be used for NIST and UKAS traceable volumetric flow measurement. Alternatively, the multivariable version may be used for density compensated mass flow or volumetric fow corrected to reference conditions, where dp, true static pressure and temperature are measured on single device.

tekProbe PR3 is compatible with any proprietry dp cell of suitable low range capability. However, Tekflo guarantee operation to specification straIght of the packing crate using its own low range, nanotechnology tekFab DP2 and DP4 Cell.

The tekFab DP2 all-digital, multivariable dp cell embodies two nano molecular crystal silicon resonators, vibrating at their natural frequencies. When the tekProbe dp is applied across them, a +ve resonator vibrates in compression mode, and a -ve in tension mode. The differential frequency provides the dp signal, while the tekProbe’s true static pressure provides an unmatched total system flow accuracy, repeatibility, resolution with zero hysteresis.

The tekFab DP4 is a low cost, nanotechnology, variable capacitance dp cell, it is non-multivariable, but without compromising accuracy and stability.

(See separate tekFab DP02 and DP04 Cell specifications)

- Flow coefficient non-linearity :

.+/- 0.5% of reading > 0.5 m/s (1.6 fps) liquids, over 4 : 1 range

.+/- 0.7% of reading over 6 : 1 range

.+/- 1.0 of reading over 10:1 range

Reynold Numbers > 50,000 for gases and steam

Note : Liquid flow cavitation due to insufficient static pressure, gas adiabatic compression factors, or Mach number effects may cause non-linearity deviation.

Consult factory for liquid mean velocities > 3.5 m/s (11 fps), or gas / stem applications generating > 500mm wg (20″ wg) - Unrecovered Pressure Drop :

Unrecovered head loss as tekProbe PR3 with 50mm (2″) insert tubes have

negligible pressure loss % of differential pressure : in pipes > 1000mm (40″)

tekProbe Pipe Diameter or Minimum Duct Dimension mm 50 80 100 150 250 450 760 > 1000 inches 2" 3" 4" 6" 10" 18" 30" > 40" PR3 - 25 - - - - 6% 4% 3% Negligible PR3 - 16 9% 7%" 6%" 5% 3% - - - - Maximum Pressure for insertion Under Pressure :

tekProbe PR3 with 16mm insert tube diameter : 10bar max (145psig)

tekProbe PR3 with 25mm insert tube diameter : 4 bar max (60psig)

tekProbe PR3 with 50mm insert tube diameter : 1 bar max (15psig)

Under pressure insertion version not available for steam

Without flanges, Styles B and C, max 16 barg (232psig)

With flanges, Style A, according to flange rating max. ANSI 600, PN64

Notes : Only flanged versions are available for steam application - European Pressure Equipment Directive :

tekProbe PR3 conform to the European Pressure Directive PED97/23/EC, Article 3, Second Engineering Practice (SEP), Table 7 Group 8 Group 1, and Table 9, Group 2 up to the specified tekProbe PR3 pressures. - Maximum Temperature :

Without flanges, Style B and C, maximum 150°C (300°F).

With flanges Style A, according to flange rating max. ANSI 600, PN64 - Material of Construction :

AISI 316 stainless steel throughout, except optional brass shut-off valves. tekProbe PR3 Style C with brass shut-off valves are fitted with a brass/bronze isolation valve and epoxy protected carbon steel pressure chamber. For other materials, consult Tekflo or Local Authorised distributor.